Abacusynth: Spinner Fabrication

April 10, 2022

Thesis

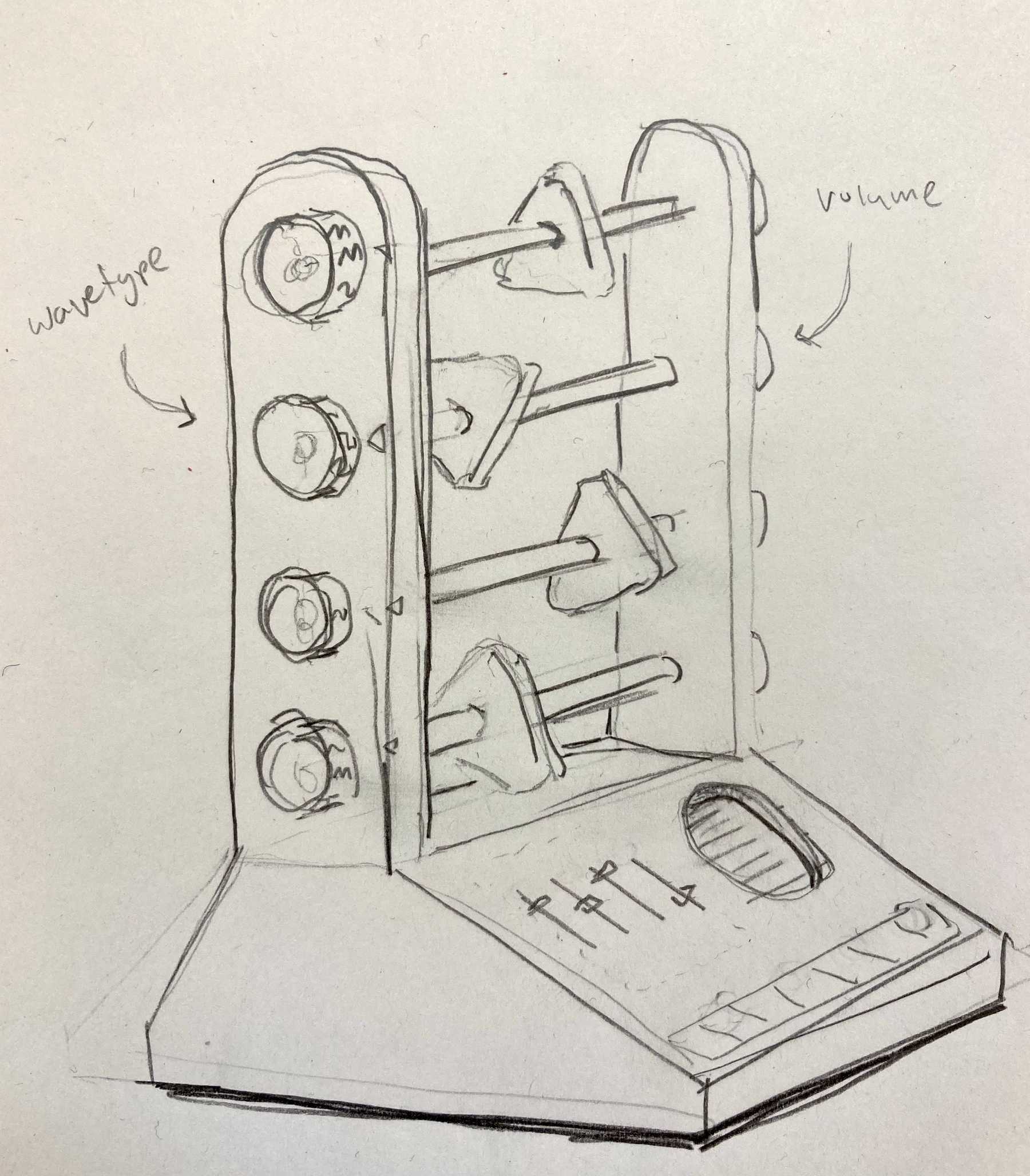

Sketch of my thesis project: Abacusynth

Sketch of my thesis project: Abacusynth

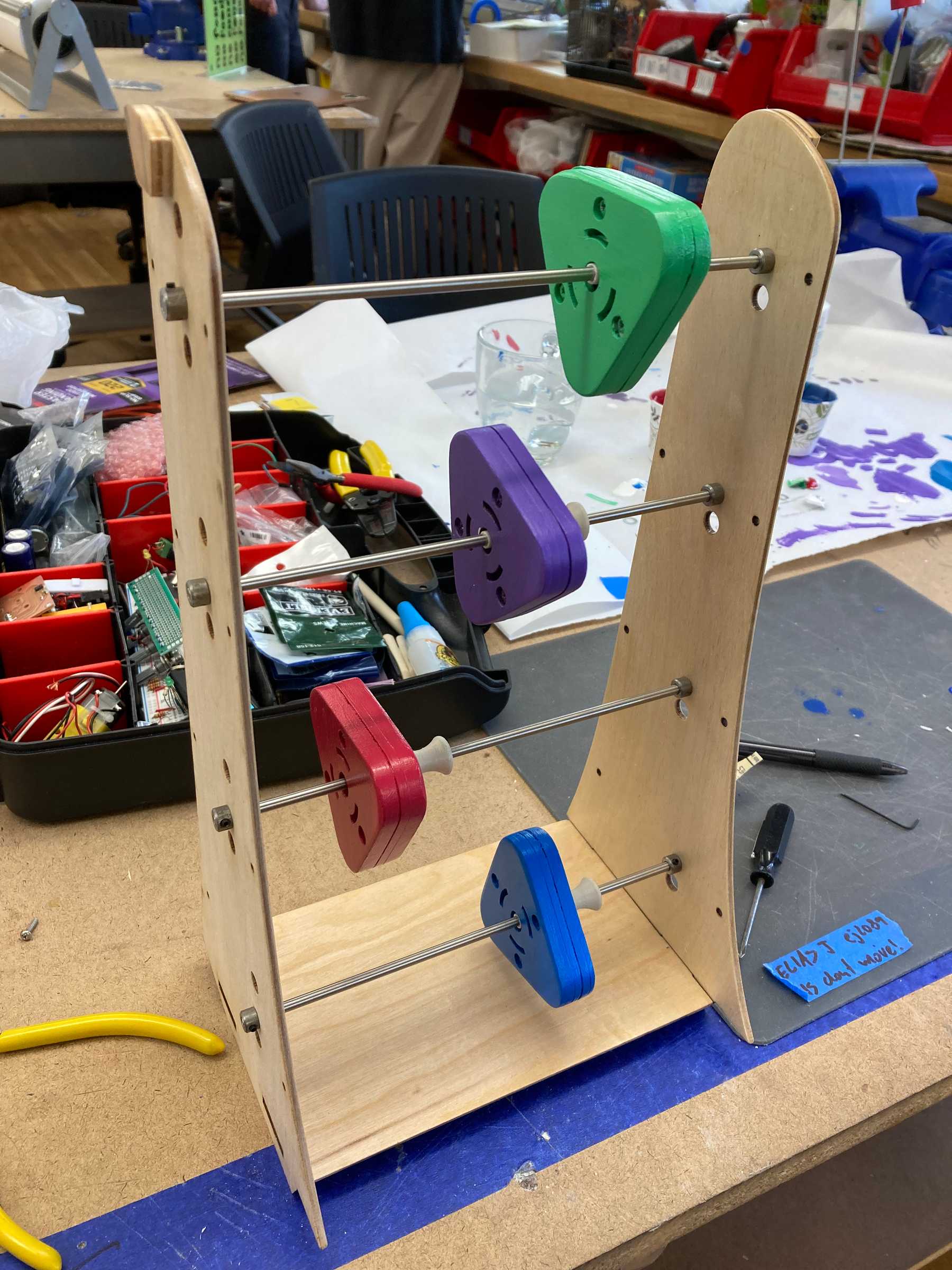

For my thesis project I am creating a synthesizer inspired by an abacus. Its interface consists of four rods, each holding a spinning object. These four objects represent oscillators in the synth. A user can spin them and move them left and right along the rod.

The objects should be as “spinny” as possible, but they also need to move left and right smoothly. I experimented with a lot of ball bearings, but nothing worked as well as a fidget spinner. I wanted the objects to be wood, so I found a small spinner and encased it within within layers of laser-cut wood.

V1: Minimal Spin

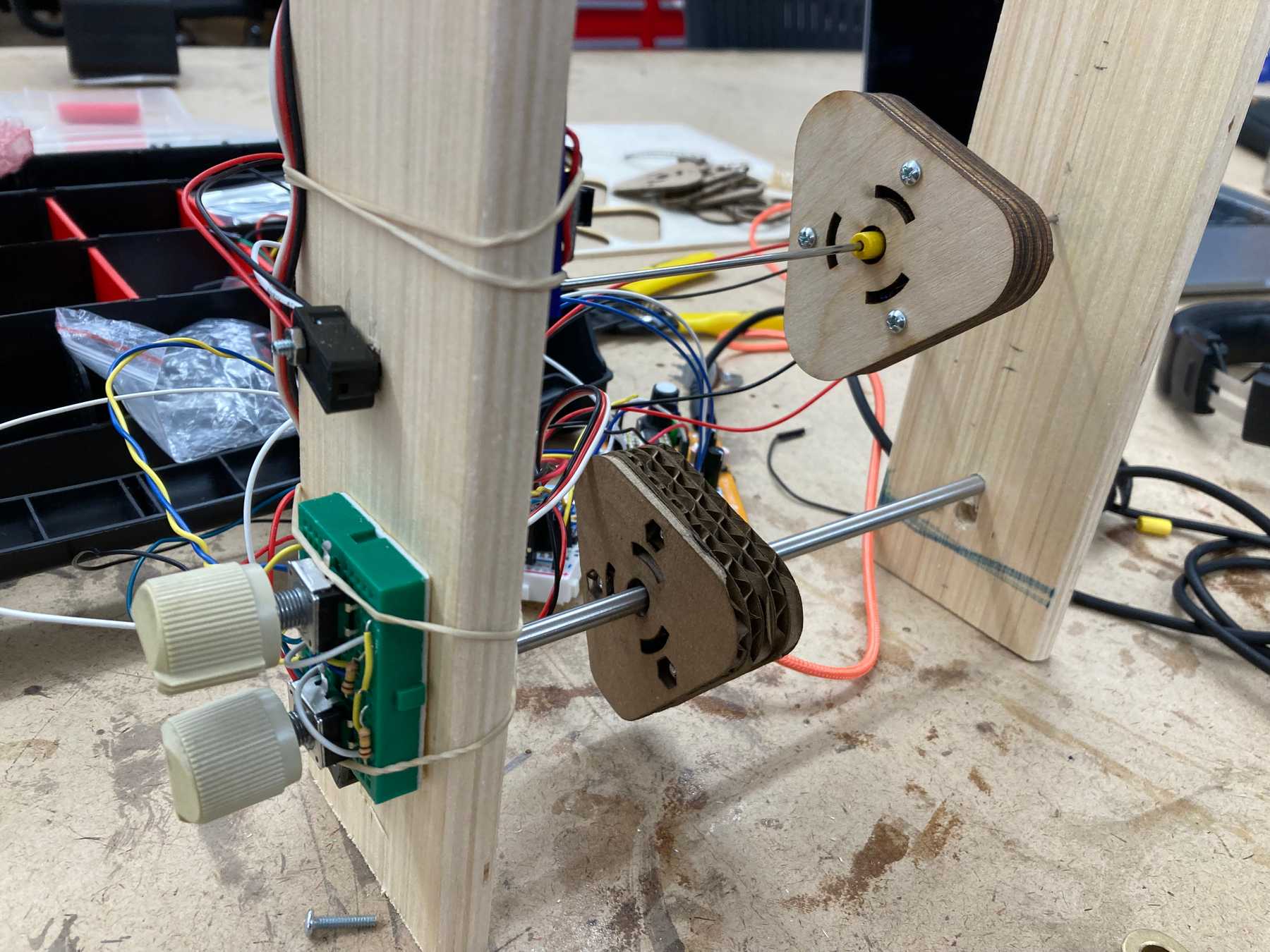

Initial prototype using a bushing for the rotation

I started with using a bushing to spin/slide the object. It slowed down pretty quickly.

Testing a Fidget Spinner

Testing a fidget spinner with the breakbeam sensor

Hoping to not reinvent the wheel, I ordered some fidget spinners. They performed exactly as I envisioned — spinning for multiple minutes. I even found one that had slots already cut out of it, which would allow me to use it with my break-beam setup perfectly.

A more compact spinner featuring slots

Testing both spinners at once

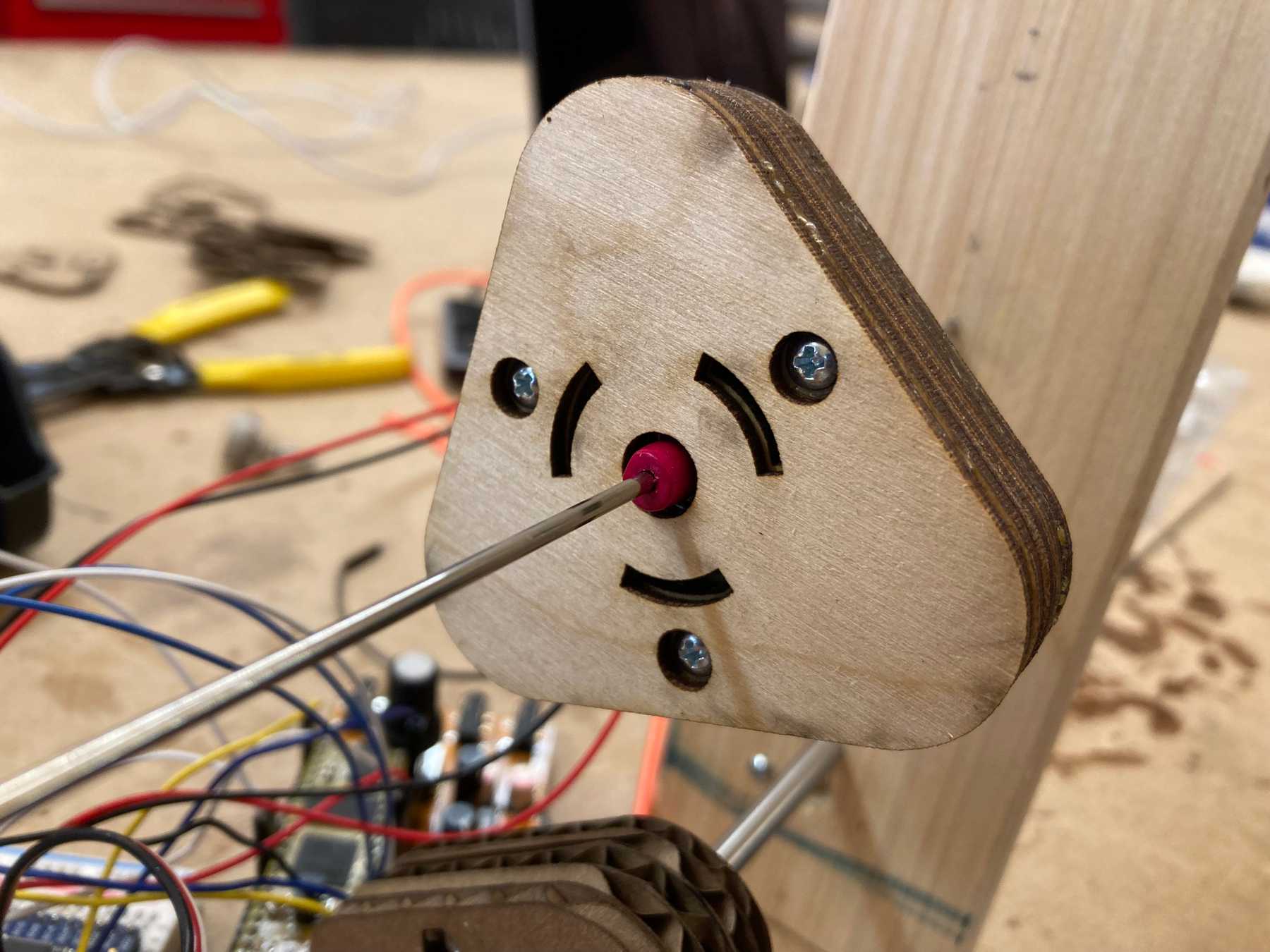

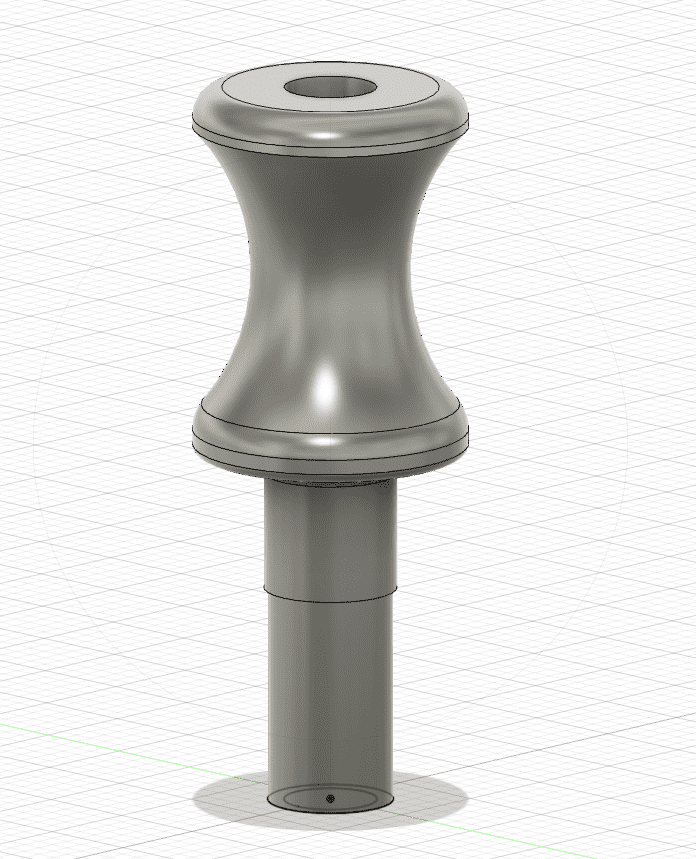

Building the Housing

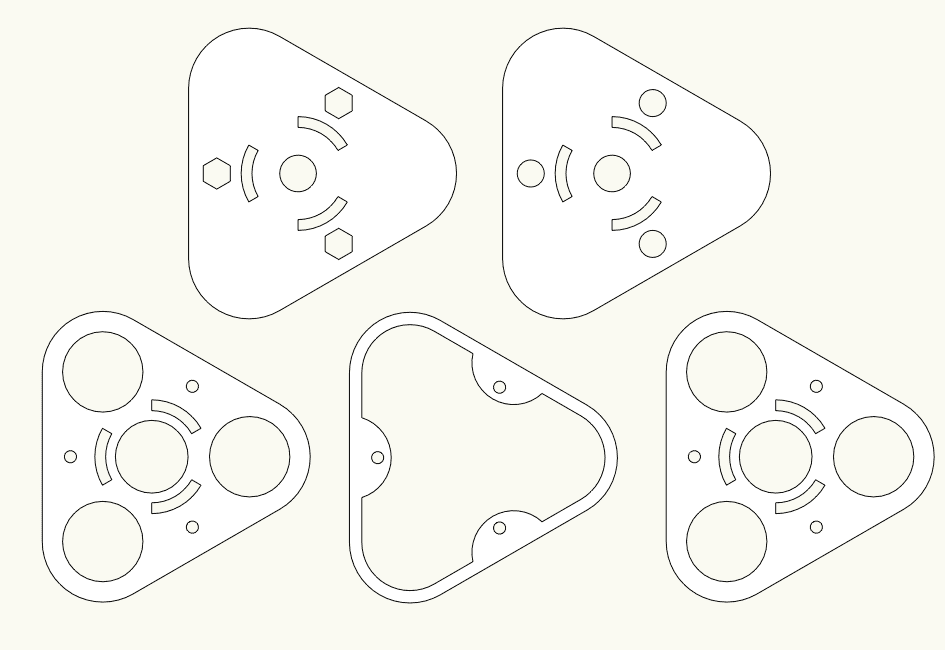

I designed the housing in Vectorworks. It consists of 5 layers of 1/8” material held together with bolts, that when assembled, encase the spinner tightly.

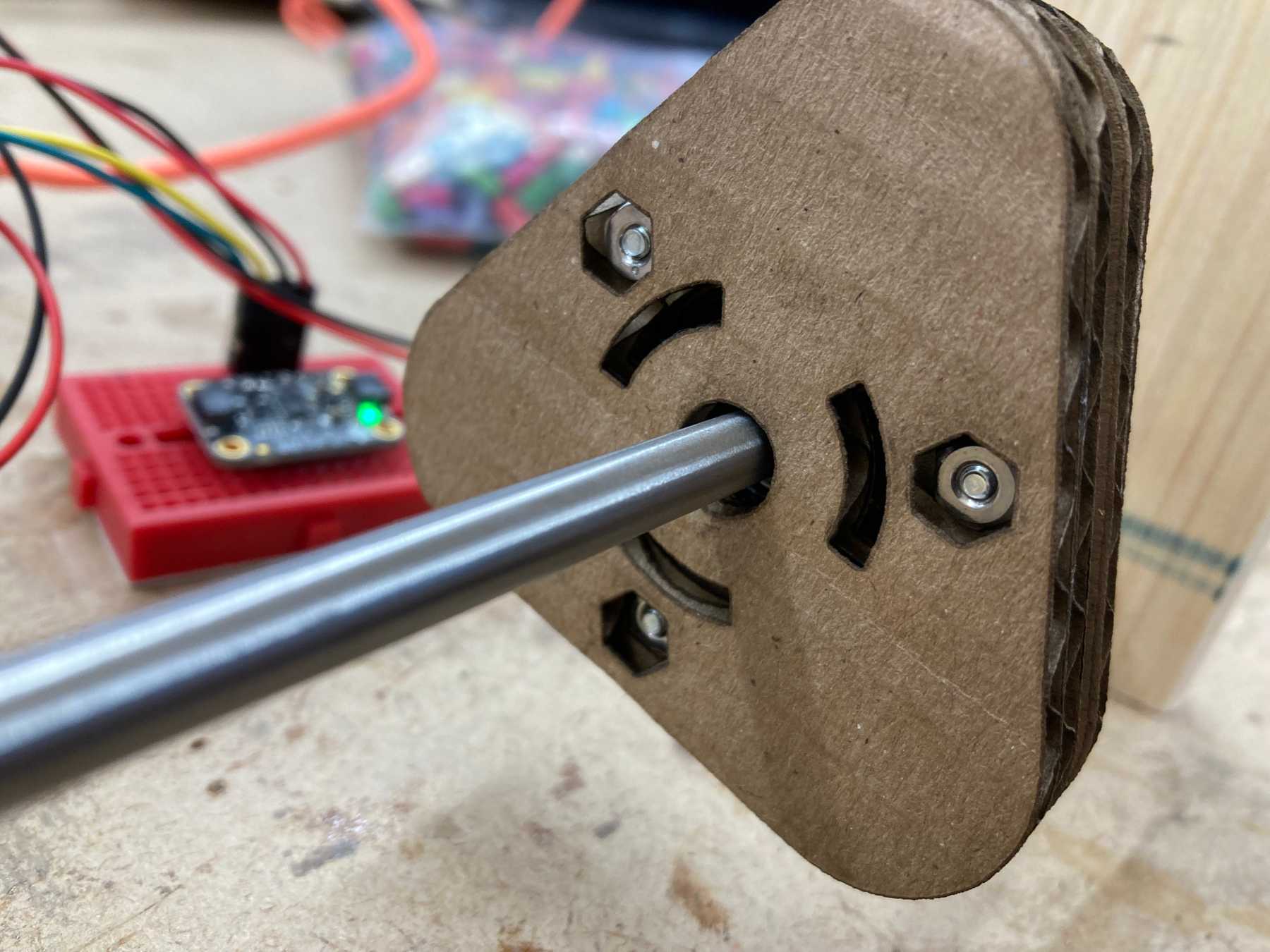

Cardboard Prototype

I started with cardboard to make sure everything fit.

Testing the spin — pretty good!

It worked pretty well! I just needed to make the holes smaller to fit 4/40 screws.

Wooden Version

Laser cutting the wooden pieces

Laser cutting the wooden pieces

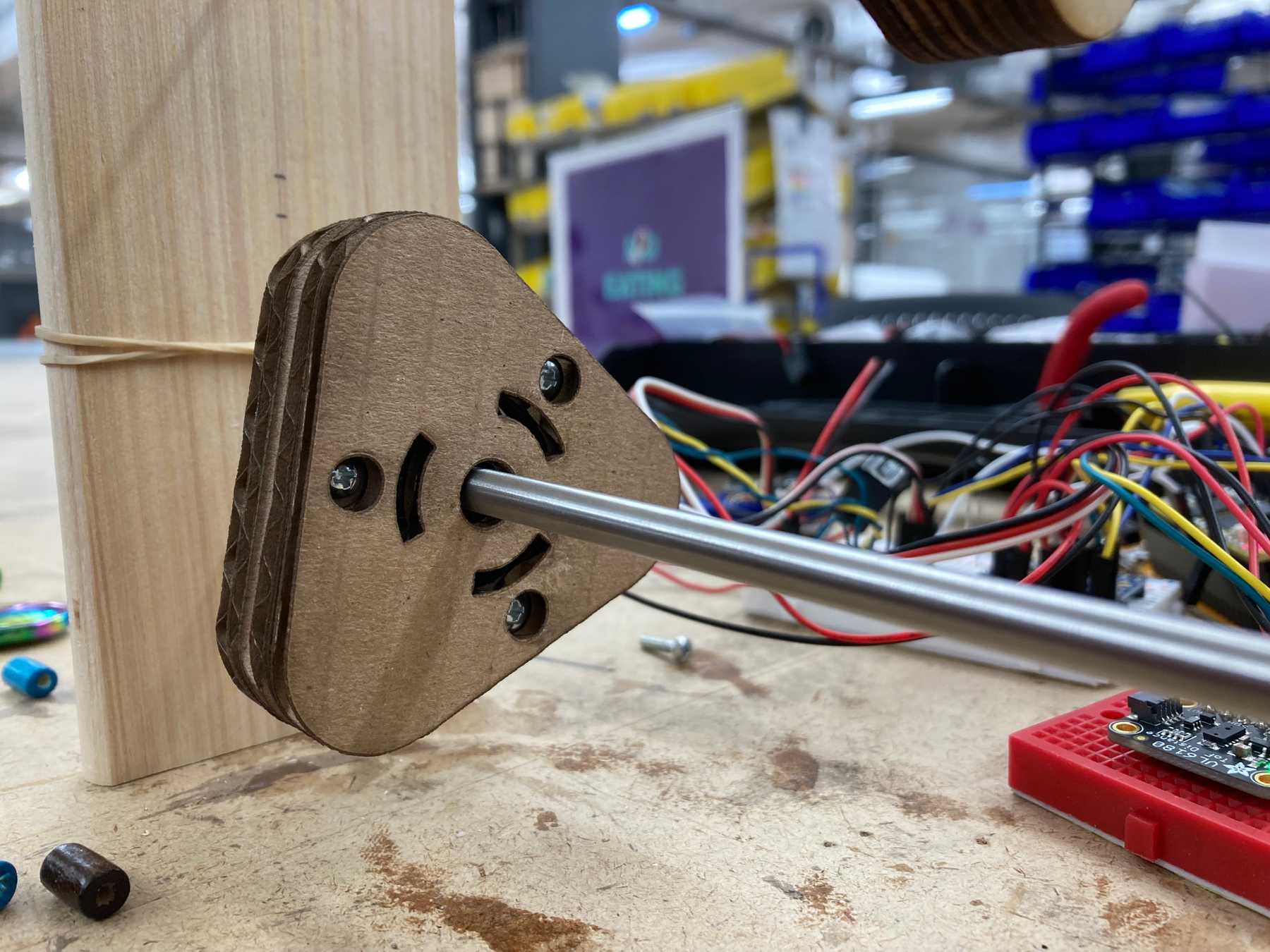

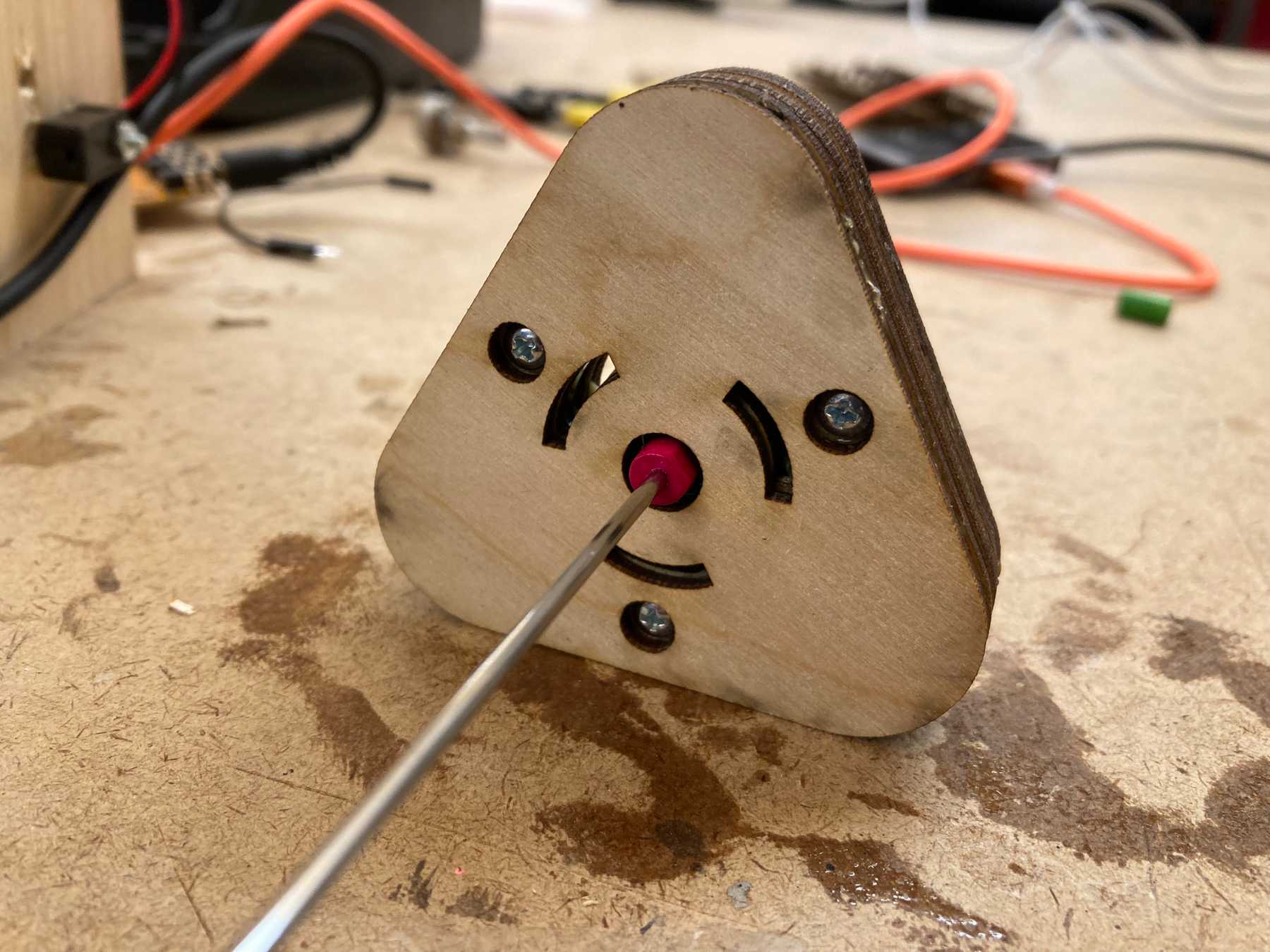

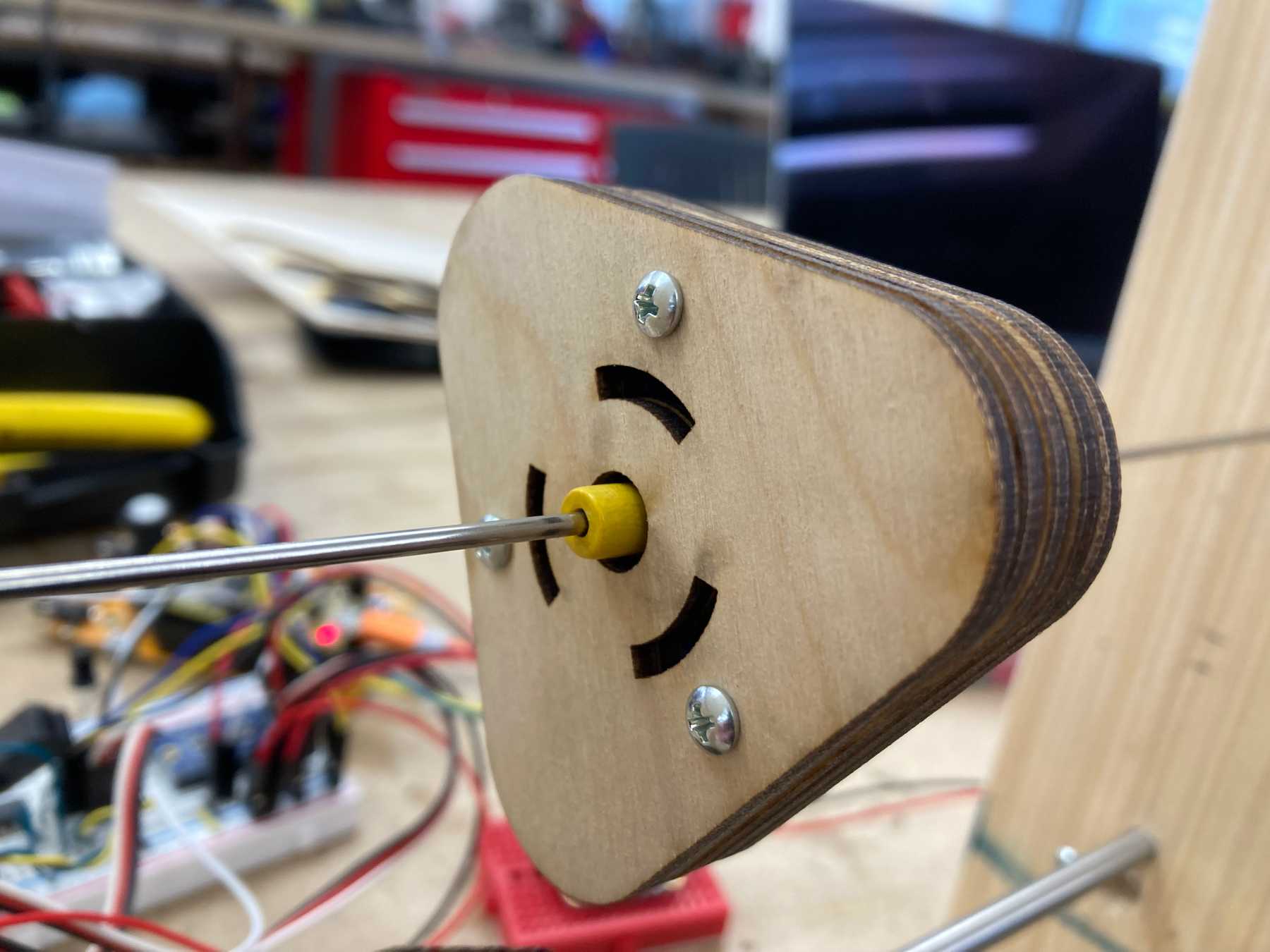

The assembled enclosure: front

The assembled enclosure: front

The wood is a bit thinner than cardboard, so there is a slight gap on the edge, where the inner metal is visible.

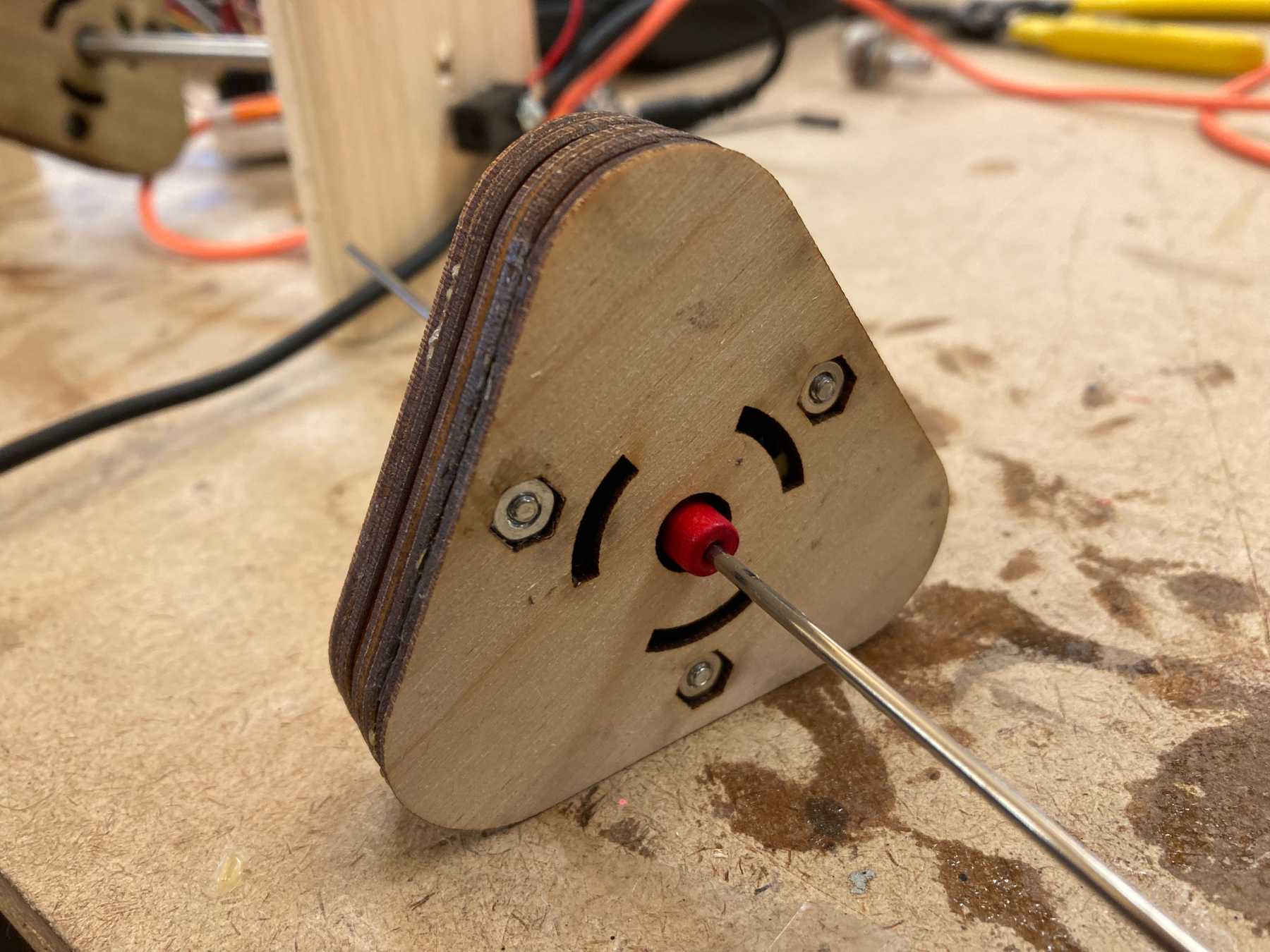

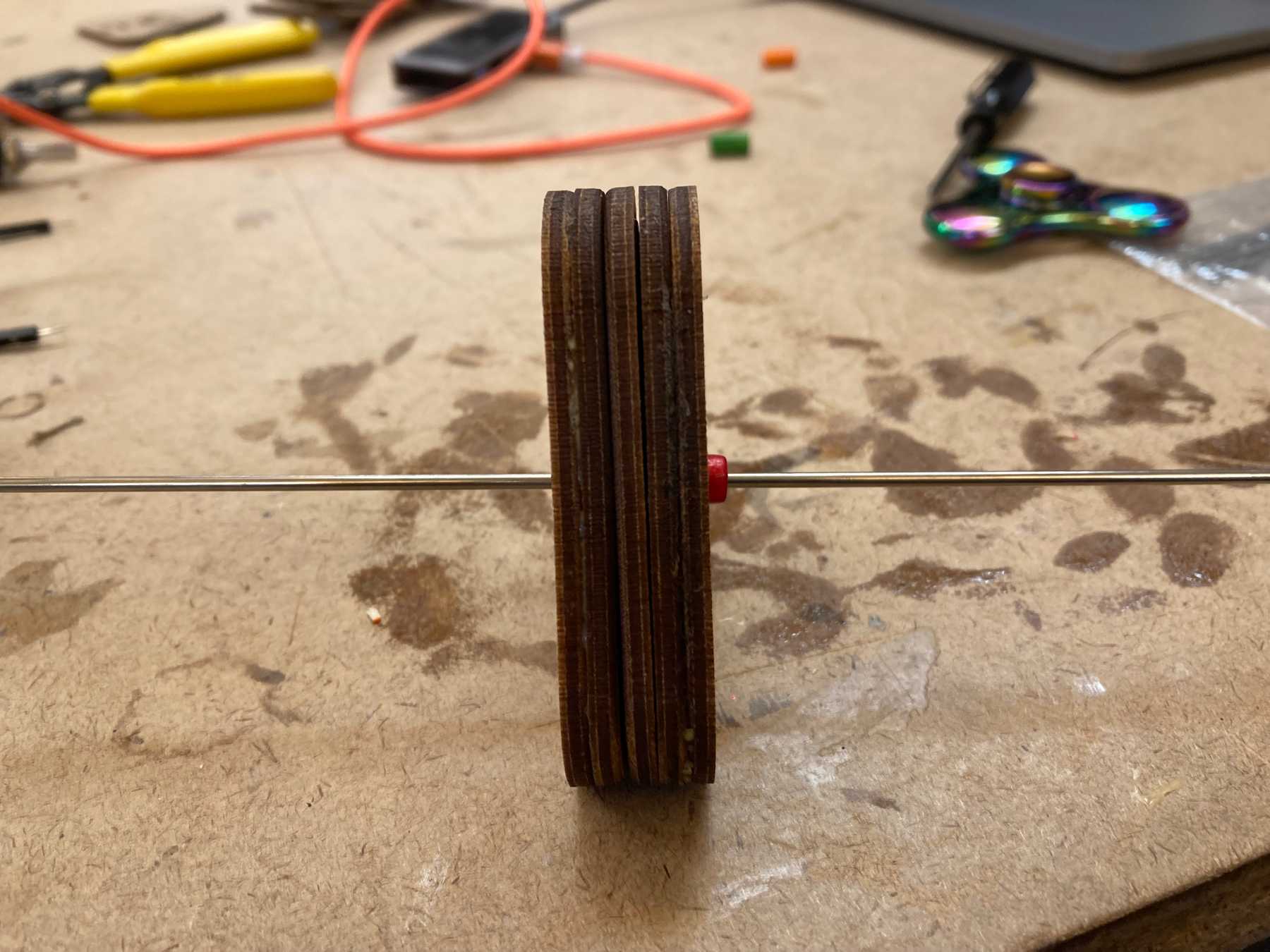

The assembled enclosure: profile

The assembled enclosure: profile

The wooden piece feels very satisfying to spin

It feels great to spin, but there’s an issue: the bolts stick out dangerously. To solve this I designed the outer two layers such that they would countersink the bolts.

Countersinking the bolts

The front and back panels would need to be glued to their adjacent layer in order for this to work, since the bolts no longer hold them

Cardboard Prototype

Back to cardboard…

Wooden Version

On to wood…

Much safer and looks better!

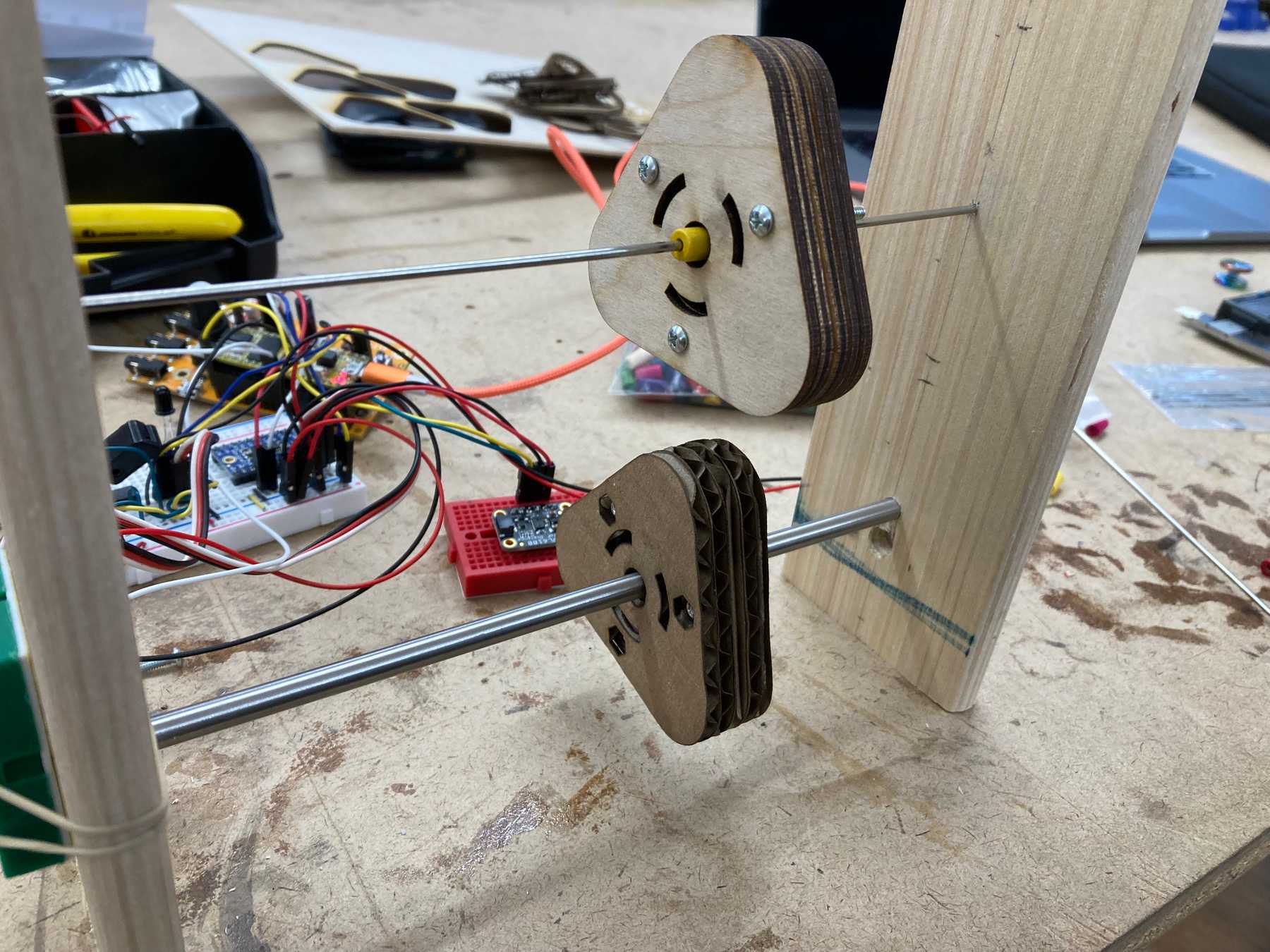

Slide Mechanism

The spinners need to slide left and right smoothly. The inner diameter of the bearing is 1/4” in. I tested using a 2mm rod and wooden beads. They moved quite smoothly, but the rod was too thin to remain rigid, especially when the object was in the middle.

A wooden bead inserted into the bearing

A wooden bead inserted into the bearing

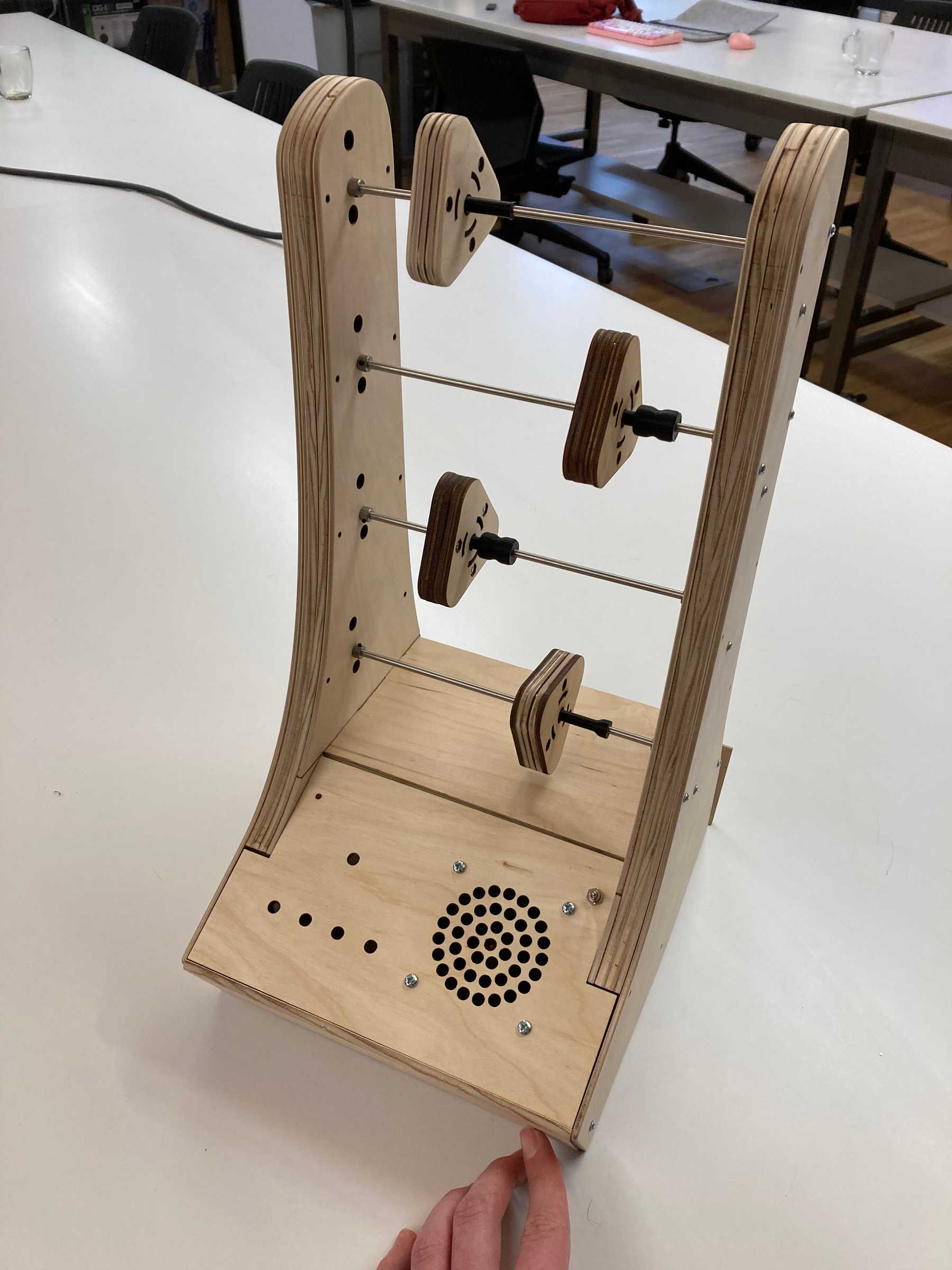

Testing two Spinners

Testing both spinners at once

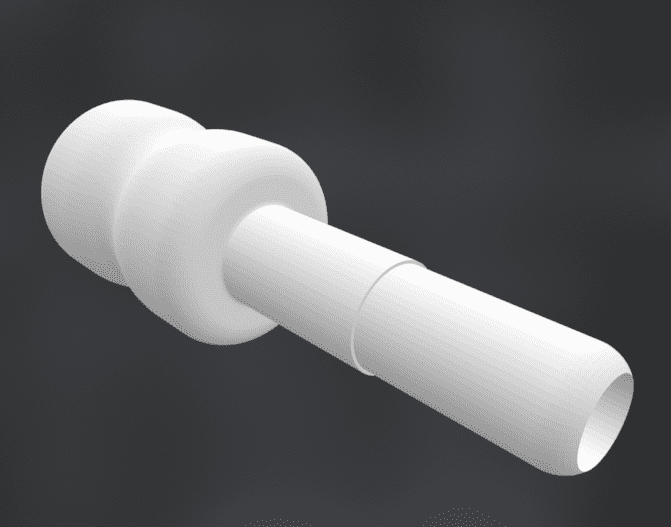

3d Printing a Handle

For the final iteration, I 3d Printed a handle that would friction fit into the spinner but allow for easy left/right movement.

Version 1

Assembling the spinners with the two new handles and some earlier tests

Assembling the spinners with the two new handles and some earlier tests

Final Version

User testing revealed that the spinners should fit the finger better, with a wider curved handle. I updated the design accordingly.

I sanded the new handles and, after painting the spinners, assembled everything together.